Production

Our

Lines of Activity

Our business lines

Our business lines are the provision of technical support for the development of electronic products and systems, the complete engineering of the product through the definition of the production process, the creation of masters for printed circuits and the creation of the technical documentation necessary for production.

Design

Process

From Mastering to Engineering

The design process starts from the customer, who is followed and supported in the mastering and engineering phases of the product, with high quality results and cost avoidance.

Strategic

Consulting

Choice of Strategic Components

The consultancy provided in the choice of strategic components is also very important, at this stage. GIBIESSE also offers support to the customer for the development and design of Hardware and Software, taking advantage of a team of long experienced external consultants.

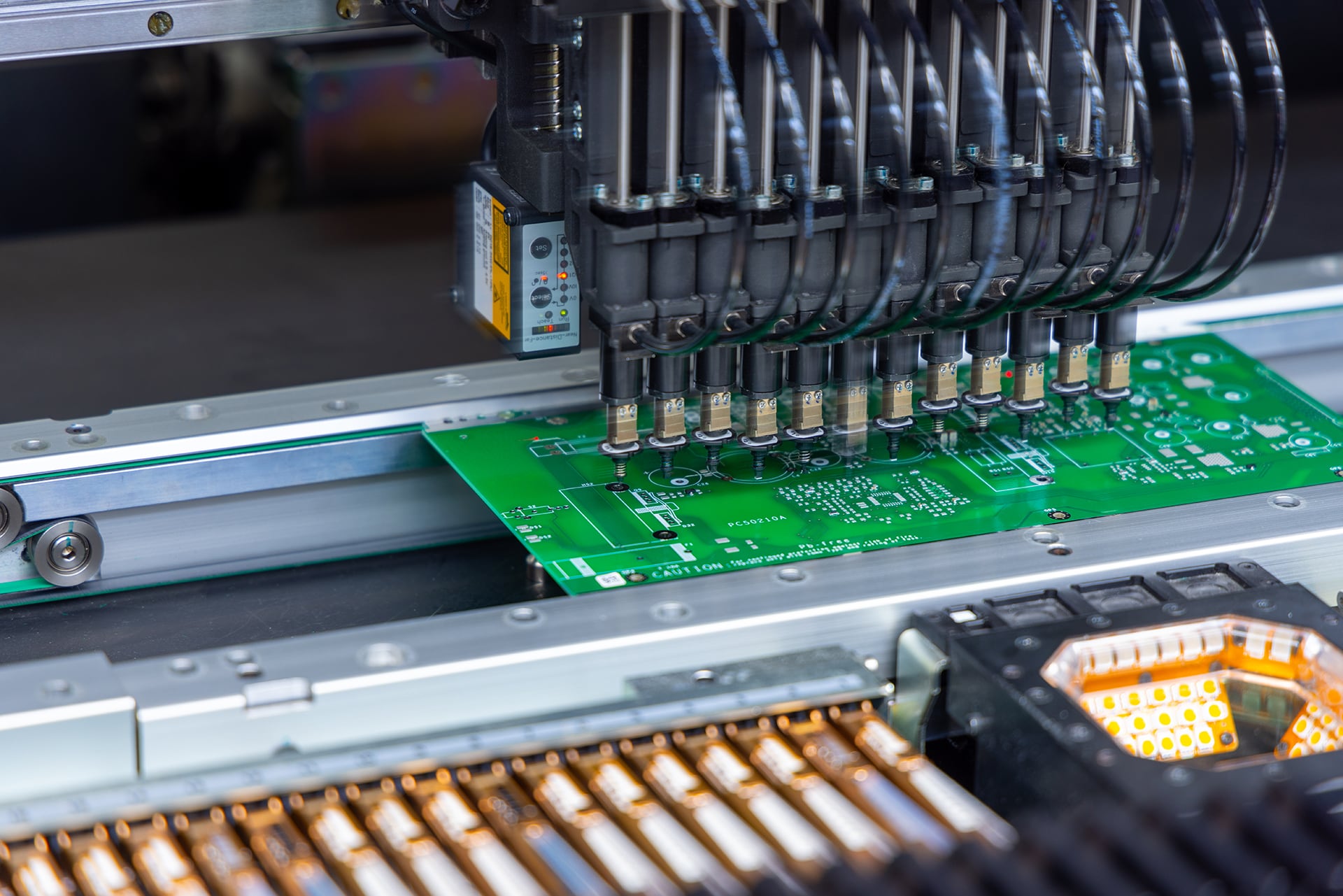

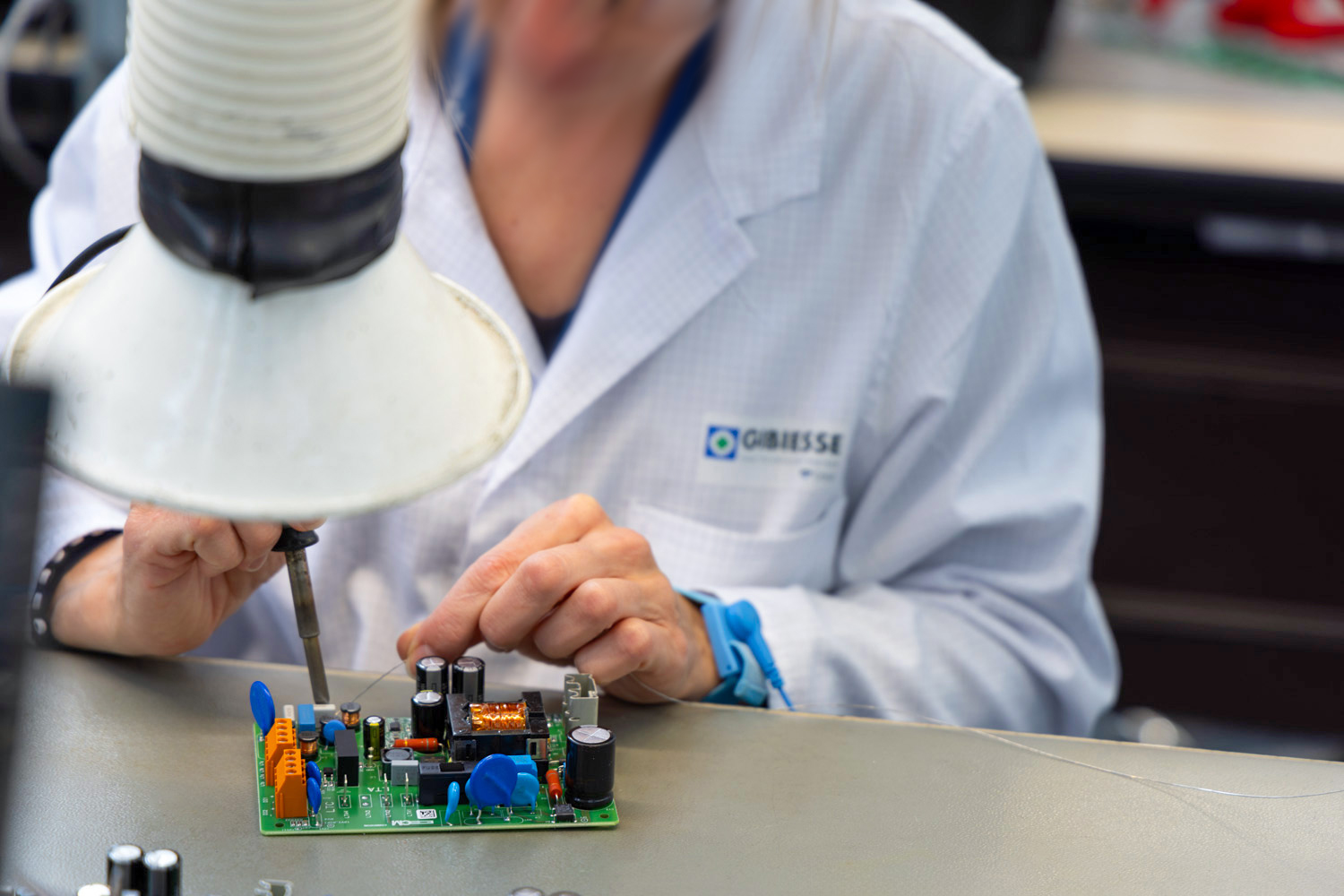

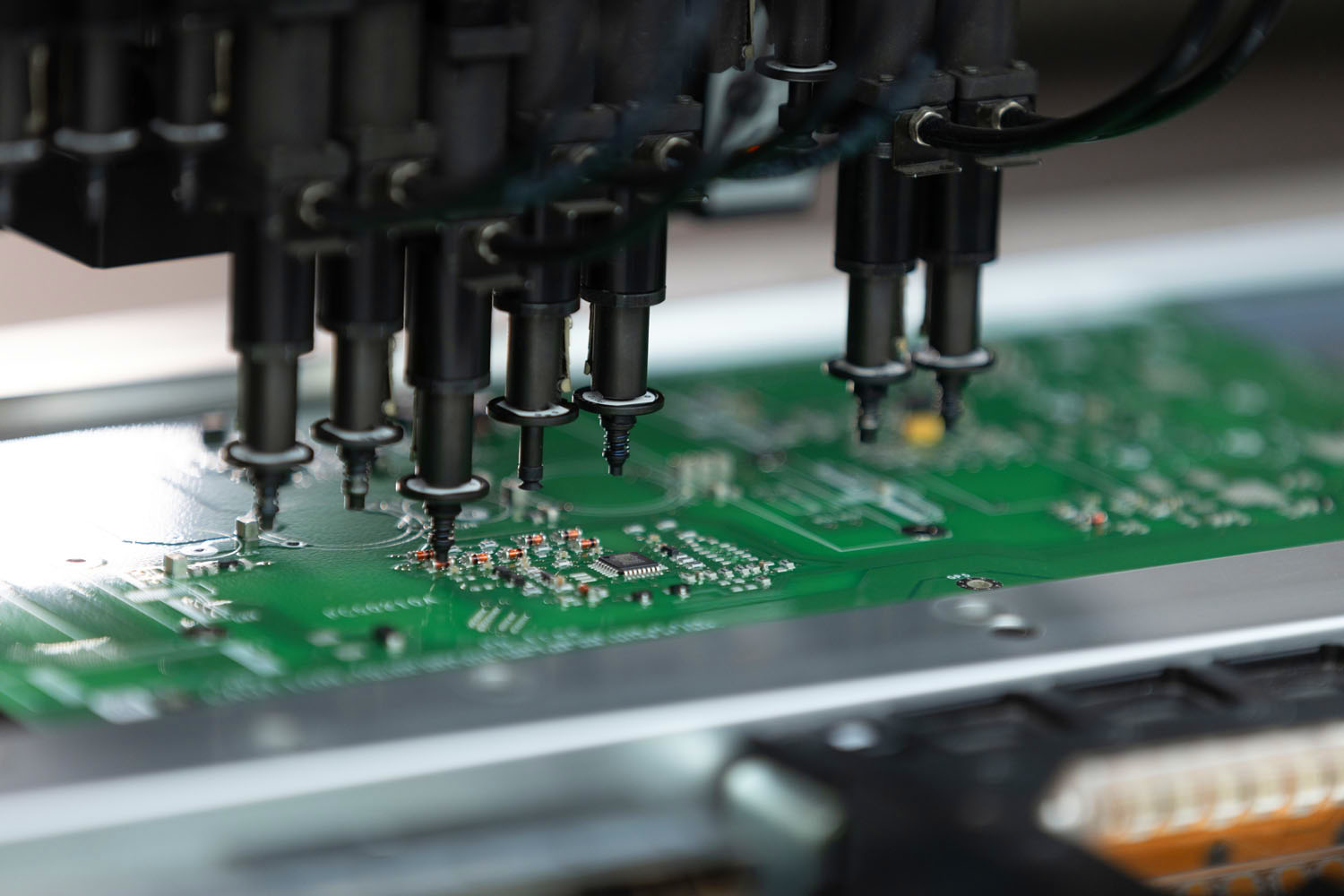

Assembly

Line

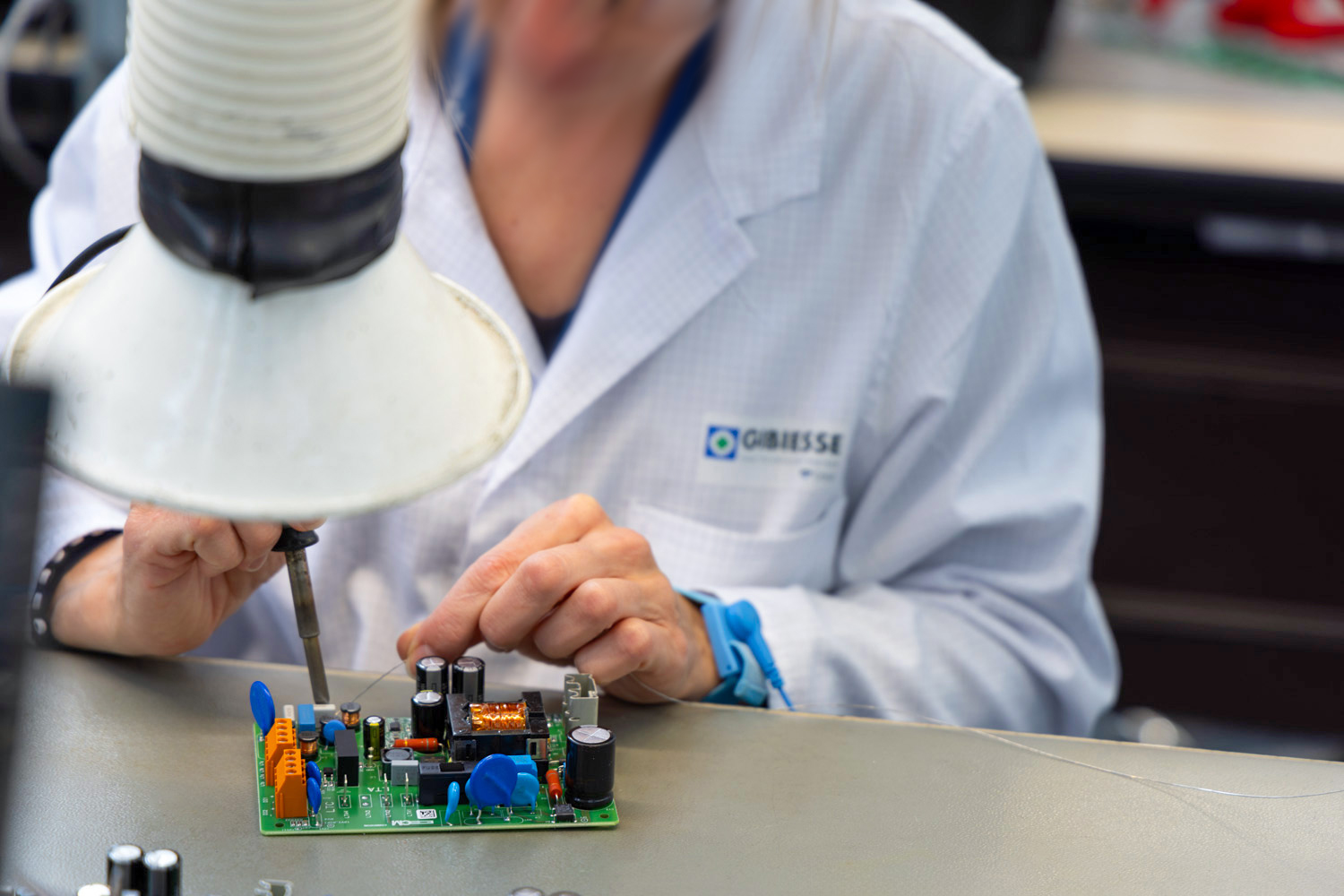

THT and SMT assembly

GIBIESSE has a complete THT and SMT assembly line with highly qualified personnel.

Some of them are also trained with IPC courses and relative certification (SPECIALIST or TRAINER, based on the training level) recognized worldwide in our product sector. Production is entirely carried out at Inzago plant, which stands out for its large serial production capacity. This allows us to follow the processes step by step and guarantee high quality standards.

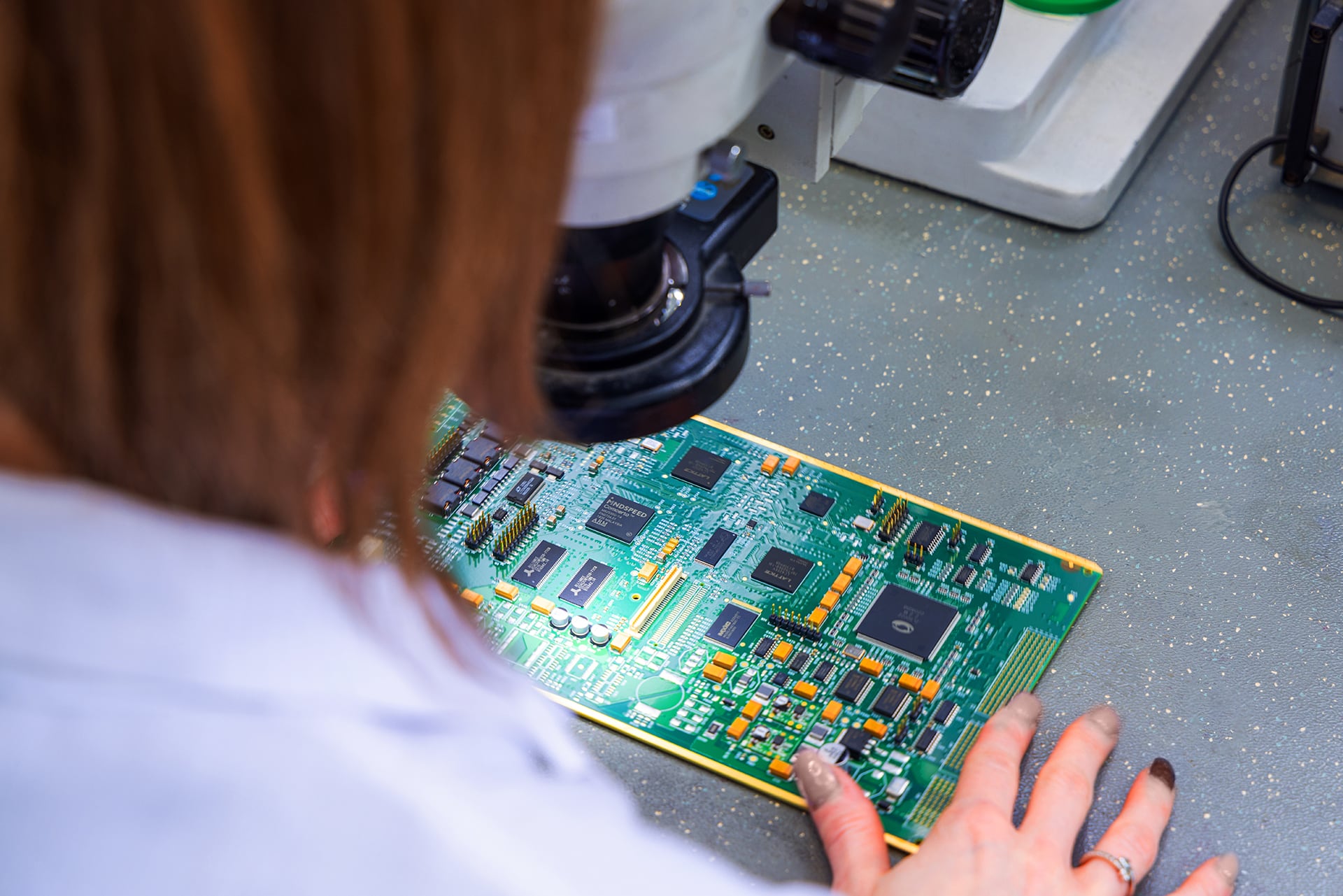

Quality and

High Standards

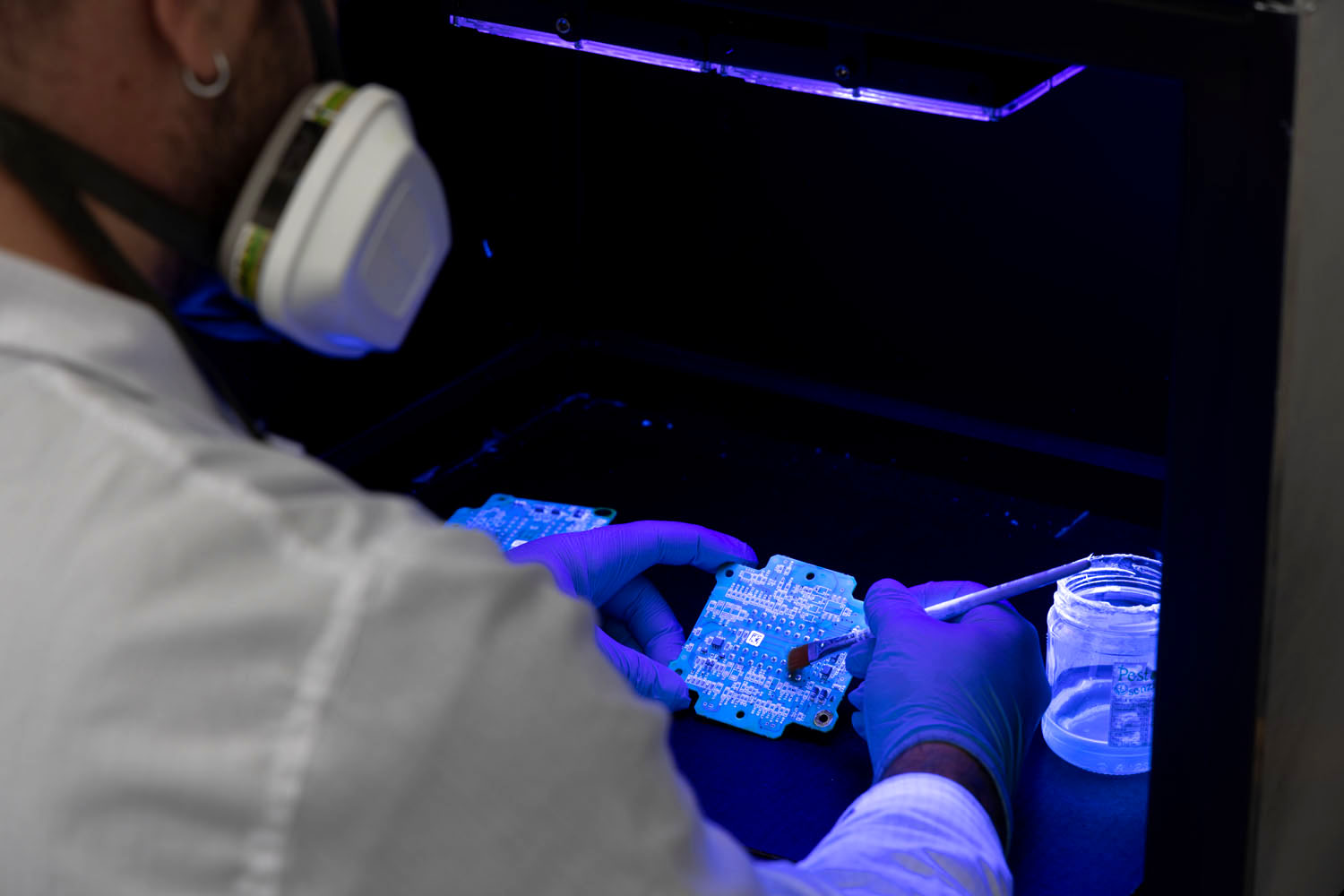

Quality Processes and Repeatability

The high quality processes at Inzago plant allow the replication of processes so that quality standards are always guaranteed. Each production stage is supervised to ensure that the finished products always meet the most demanding requirements.

High quality and standards

We optimize and complete the product by offering many services such as:

We also guarantee a complete traceability service, both for the product and the process. For any card, it is possible to know which machines it was produced with and with which transport document each individual component was purchased.

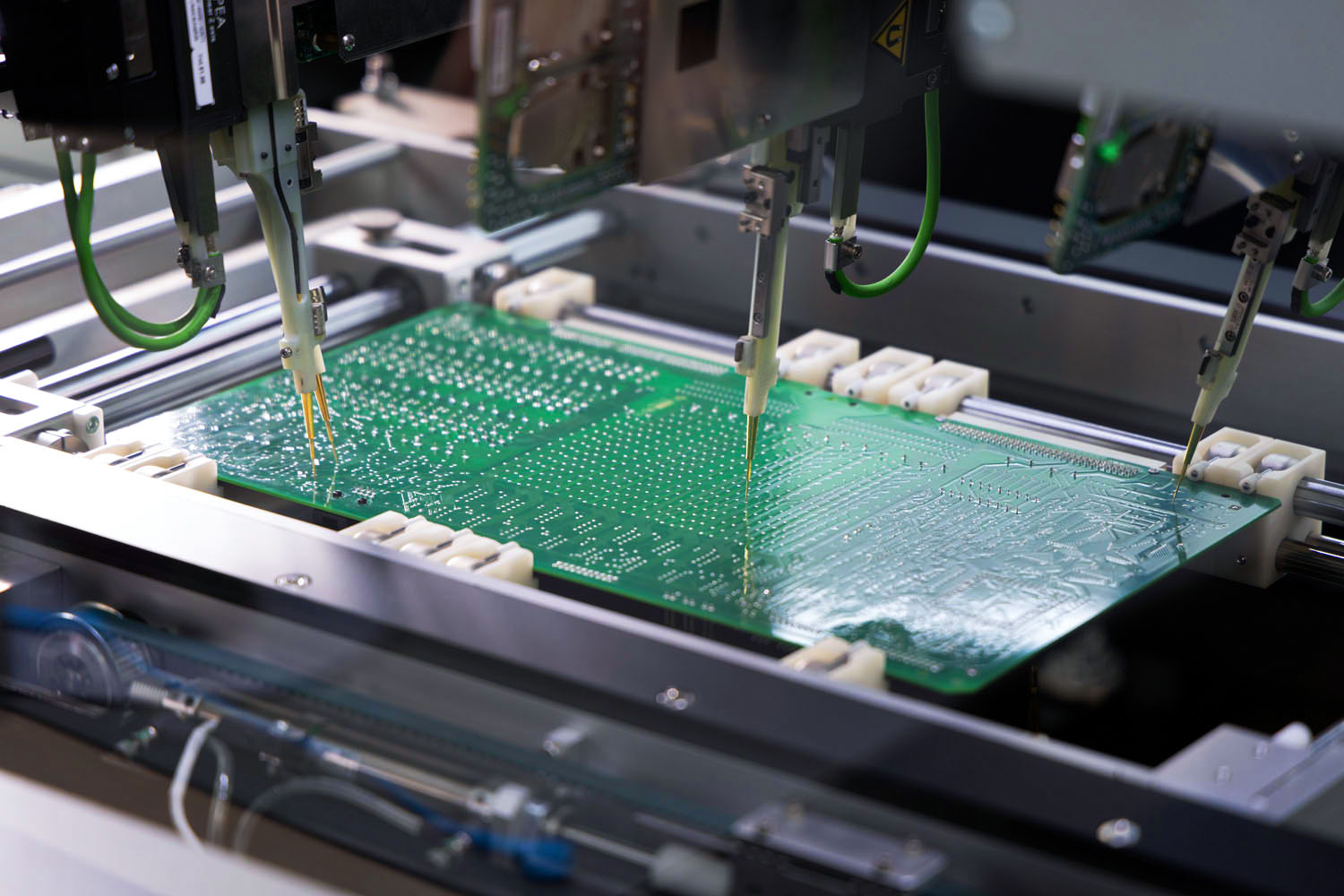

Testing and inspection

We perform a lot of different kind of test and inspections